How Fortis Construction saved $3 million in 3 months with VR BIM reviews

Fortis Construction used virtual reality to review BIM more efficiently and prevent $3 million in rework on a large data center project in Singapore. Learn how VR can help your construction process today.

Virtual reality BIM reviews are helping companies like Fortis Construction build critical infrastructure more efficiently by allowing them to inspect buildings before they’re built. For a new state of the art data center in Singapore, Fortis used Resolve and Meta Quest VR headsets to avoid $3 million worth of rework - all in just 3 months using Resolve.

Celebrating its 20th anniversary in 2023, Fortis Construction has rapidly ascended to become one of the leading general contractors in the United States and was recently ranked in the top 5 data center builders by Building Design + Construction.

With a strong portfolio across a variety of industries, Fortis prides itself on a people-centric and relationship driven culture. So it should come as no surprise that Fortis has embraced collaborative VR reviews with external partners to improve collaboration, save time, and avoid costly rework on their most complex projects.

Numbers at a glance

- 9 companies collaborating in VR

- 30 users reviewing BIM in VR

- $3 million saved from avoided rework

- 1.8 million sq. ft. data center reviewed in VR

Summary of benefits

- Reduced costs and delays from rework

- Fewer issues missed compared to traditional Navisworks reviews

- Reduced risk in Design for Manufacturing (DfMA) process

Adopting VR to review an 11-story data center

Building off the success of a Fortis project in New Mexico that had deployed Resolve, a Singapore-based Fortis team engaged Resolve for VR reviews of a data center project. Construction in Singapore presents a unique set of challenges due to the scarcity of land in this densely populated and rapidly growing city-state. With limited space for new development, critical infrastructure projects require innovation to make the most of the available space.

Due to these unique challenges, the Singapore data center adopted a vertical design, compressing an entire campus into an impressive 11-story build. The new configuration necessitated the use of highly congested mechanical, electrical, plumbing and fire protection (MEPF) services, and Fortis proposed the use of VR to aid in the delivery of what has been called one of the most complex data center builds ever.

Challenges adopting VR for complex MEPF Navisworks models

Fortis makes sure their model reviews look beyond clashes, also spending time on reviewing accessibility, safety, and future maintenance. Since the design was so congested, it was critical to ensure the accessibility of telecom trays, containments, mechanical valves, mechanical dampers and other equipment.

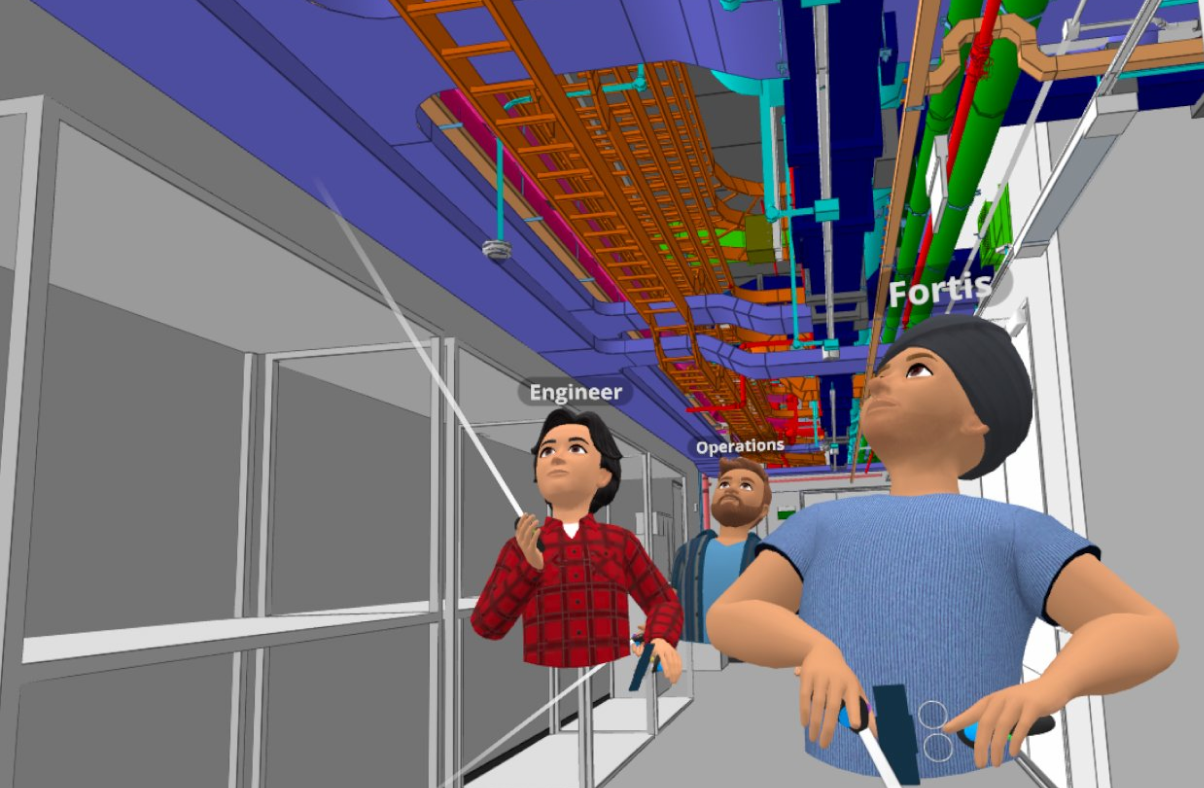

In conventional methods of design review, one person navigates through a Navisworks model while everyone else follows along on a screen. Reviewers can overlook critical issues and entire areas due to the lack of access to the model beyond what is shared on the screen.

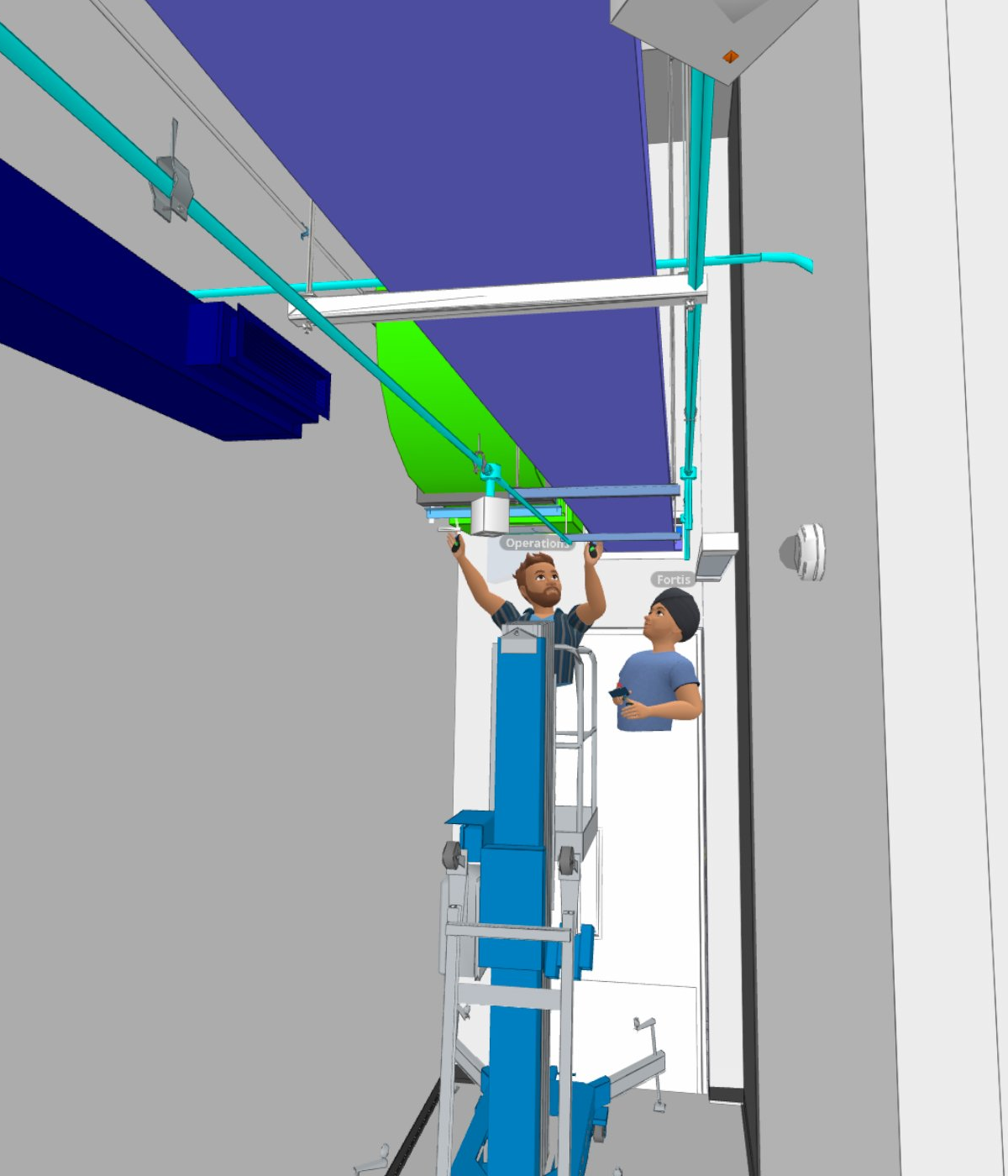

The Fortis team found that VR headsets were a good way to identify non-clash issues that were just as critical to address. By immersing themselves in the building reviewers are able to virtually role-play installation or maintenance procedures, allowing them to provide feedback that they normally wouldn’t give until late stage site walkthroughs. Of course, feedback provided at site walkthroughs causes delays and rework, so identifying these issues during design review saves time and money.

Fortis saw the potential in VR reviews, but the fully federated Navisworks model for the 11-story Singapore facility was extremely complex, and this presented a challenge for seamless adoption of VR. Before adopting Resolve, the team had to tether their headsets to big, clunky computers and spend hours downsizing models just to get them to work in VR - even with expensive GPUs on their PC!

They were finding value in the use of VR but the complexity of the process was not sustainable, and deterred a wider group of users from engaging with VR reviews.

“Over the past decade, Fortis has tried many different software solutions to implement effective AR/VR reviews of our BIM models. Despite our best efforts, none of them increased our efficiency as they were ultimately add-ons to the processes we had established. Resolve is different. We have been able to reduce processes by adopting Resolve. Subcontractors and design consultants have flocked to the VR review sessions because it saves them time in completing their design reviews and sign-offs.”

- Todd Andersen

Senior MEP Project Manager, Fortis

Upgrading BIM reviews in VR with Resolve

When the Fortis team first heard of Resolve there was some doubt that it would be any easier to use than all the other VR software they had tried. The team was working on one of the most complex BIM files in the company’s history, and didn’t think it was possible for the file to run on a Quest without any PC connection. Then they tried Resolve and opened the data center model on a wireless Quest 2. Their workflow was completely transformed and they saw what was possible when VR is made simple.

Resolve's Wellington engine is able to process massive models on untethered headsets, eliminating the need for VR caves, high-powered laptops, and long and tedious screen shares. With Resolve, a wide range of stakeholders are able to review models and provide critical feedback more efficiently.

“Resolve software had a tough start with staff members being skeptical about the value it would bring. But after a couple of sessions, it was clear how it helped locate challenges that could have been hard to see in other software… When you get the hang of it, then I see it as a faster workflow than the traditional way of coordination.”- Trols Bisbjerg, BIM Manager, Cundall

Equipped with Resolve and 30 Quest 2 VR headsets, the data center team set up VR reviews between collaborators from 9 different geographically distributed companies. The VR reviews have helped the project team find and correct more accessibility, safety, and future maintenance issues than they could have by conducting reviews using screen shares.

Since Resolve seamlessly handled opening of the large file, various stakeholders were now able to use VR to quickly and easily understand the proposed design and make comments where needed. The Fortis team worked closely with Resolve to ensure the project was set up for a successful VR deployment: stakeholders were equipped with VR headsets, a schedule and guidelines were set for VR reviews, and the whole team aligned on best practices.

Saving $3 million in rework in just 3 months with VR

Because of space constraints, integrating MEPF services at the Singapore project is a complex and challenging task. A single conduit not installed correctly can obstruct allocated clearance zones or accessibility to services, dampers, and valves. According to the Fortis team, the necessary rework for a single misplaced piece of equipment can cost upwards of $10,000 dollars and a one week delay.

In only 3 months of using Resolve, the Fortis team was able to flag over 1,000 potential issues during collaborative VR review sessions. Though they range in impact one thing is consistent: many of these issues are ones that are missed with traditional review processes.

Fortis estimates that the issues avoided rework that saved the project upwards of 3 million dollars and a significant delay - all in just a 3 month review period with Resolve and Quest VR headsets.

“Resolve ultimately minimized construction delays, change orders, and rework, thereby resulting in significant cost savings for the project.”

- Dushyant Negi, Fortis

Although it may seem overwhelming to identify so many issues, it gives the Singapore data center team confidence in the project and helps them resolve issues earlier. Reviewers were able to identify hundreds of equipment accessibility issues and rectify them before site installations began.

Issues found in VR

The key areas the team wanted to inspect with VR reviews were mechanical & electrical floors, data halls, and corridors. Space was at a premium and the team needed to ensure that the mechanical and electrical equipment fit in the space while remaining accessible and serviceable for operators throughout the building lifecycle. The use of VR provided an ideal way for various stakeholders to quickly and easily understand the proposed design and identify potential issues.

"I can't imagine producing the shop drawings without reviewing the design through VR."

- Hardarshan Singh, BIM Manager, Fortis Construction

During a 3-month review period, the team identified over 1,000 issues in Resolve, including:

- Issues with obstructions of accessibility to services, dampers, and valves

- Optimal placement of equipment to ensure maintainability and ease of access

- Safety concerns, such as the need for additional safety railing

- Issues with obstructions of clearance zones

- Missing elements, including supports, bracings, trays, ladders and pipes

- Design flaws, including aesthetics issues identified by the project architect

- Missing and obstructed signage, including exit signs

- Clashes and unnecessary objects in the model

Critically, Fortis underlines that many of the issues found in VR would have gone unnoticed while coordinating through conventional 2D screen share review. While Navisworks can be great for identifying and resolving clashes, many issues in the categories above go unseen until construction is in progress and walkthroughs begin. VR accelerates the timeline for finding these issues.

DfMA supercharged by VR

For the Singapore project, Fortis made heavy use of Design for Manufacturing and Assembly (DfMA). Nearly 70% of the MEPF systems are DfMA products. DfMA components are designed for ease of manufacture and assembly on site. Given the product nature of DfMA, there is limited flexibility to make design changes once DfMA components are on site. Teams need to minimize risk as much as possible before components leave the factory; get it wrong and DfMA can be more costly and wasteful than a traditional approach.

Virtual reality reviews have helped the team virtually inspect iterations of DfMA components to validate install and maintenance requirements. Prototypes of products can be reviewed at full scale in a number of ways both in VR and AR with Resolve’s app for Quest. This allows teams to review various product designs and increase confidence of what will be delivered and installed.

By reviewing DfMA products in Resolve, the team avoided rework that would present high-cost challenges if discovered on-site. Resolve plays a vital role in allowing various stakeholders to review the products, fully integrated into the data center regardless of the file size, and check the feasibility of designs with different systems.

Integrating VR into existing BIM workflows

Today, the Fortis data center team, along with external collaborators, has adopted VR as part of their standard BIM process. Collaborators are contractually required to equip themselves with a Quest for design reviews.

The BIM Execution Plan (BEP) has been instrumental in making sure that VR is adopted in an impactful and organized manner. The document helps to outline how VR fits into the model review process, at which milestones VR comments are expected, and how issues raised in VR are to be resolved.

Fortis has developed a process that empowers stakeholders to more actively engage with BIM and provide feedback that helps everyone on the project ensure successful delivery. By combining easy to use software like Resolve, accessible hardware like the Quest 2, and developing a process the Fortis team is pioneering the use of virtual reality for construction.

Do you want to upload your own BIM to review in VR? Sign up for a free trial.

Resolve builds software that makes 3D building information models more accessible so teams can find critical issues that save time and money on new construction. Resolve's Wellington Engine can render large BIM files on the standalone VR devices making it a scalable, easy to use solution for project teams. Resolve is used by leaders spanning industries like food & beverage, water treatment, data centers, biopharmaceuticals, and green energy.